|

With the development of the market, more and more speaker equipment will use NdFeB magnets to replace traditional speaker magnets. Today we come to understand the advantages and disadvantages of neodymium magnet speakers: Advantages: 1. High magnetic performance, small size and lighter weight t1... Read More

|

|

Bonded NdFeB magnets are made of NdFeb magnetic powder and binder mixed through "press molding" or "injection molding" made of magnets. It has high dimensional accuracy, can be made into magnetic components with relatively complex shape, and has the characteristics of one molding, multi-pole orient1... Read More

|

|

N52's NdFeB magnets have high magnetic energy product properties. N52 is the corresponding grade. According to the temperature coefficient, it can be divided into N, M, H, SH ranges. For example, the surface Gauss of N52 NdFeB magnet 10mm*10mm is stronger than the surface Gaussian of N4210mm*101... Read More

|

|

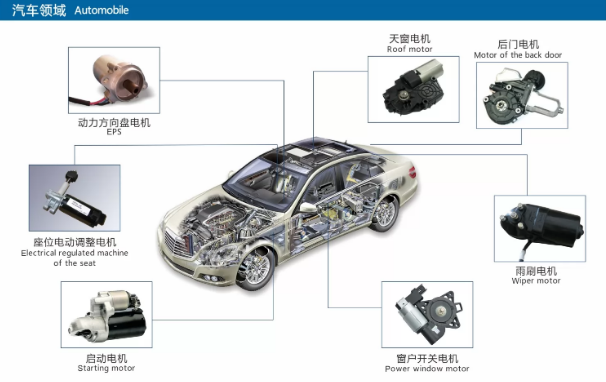

With the improvement of our living standards, magnets are everywhere in our lives. As we all know, there are many kinds of magnetic materials on our commonly used travel vehicles, including rare earth neodymium magnets, ferrite magnets, SmCo permanent magnets, which are mainly used to generate mag1... Read More

|

|

Sales status of neodymium magnets in China in 2021 Rare earth is China's advantage resource, accounting for more than 80% of the world's rare earth resource reserves. In 2021, the output of rare earth permanent magnetic materials will reach 100400 tons, an increase of 13.1... Read More

|

|

Permanent magnet materials must be packed with foam boxes, magnetic armature and bubble bags for shielding, so as to meet the requirements of air and sea transportation. (Mainly use foam plate and magnetic separator, and usually use an eight hole foam box specially used for exporting). If the magne1... Read More

|

|

After any magnet is placed for a period of time, spots of other colors will appear on the surface, gradually rusting, and it is not easy to rust after plating. The following reasons are that the air circulation, humidity and temperature difference change greatly, the dirt on the surface before magn1... Read More

|

|

NdFeB strong magnet as its name, the main manufacturing components are neodymium, iron, boron three materials, of course, there will be other element materials, after all, different products are different ingredients, and the size of the magnetic force is generated by the ratio of these key mater1... Read More

|

|

NdFeB magnet has good magnetic properties, but it is easy to be corroded and oxidized, so what changes will occur after NdFeB magnet is corroded and oxidized, and will it affect normal operation? First of all, NdFeB magnets are easy to react with the outside world because of their active surfac1... Read More

|

|

Processing process: First: the previous process Ingredients - Smelting - Throwing tape - Milling - Sintering (blank) (1) Ingredients: some mineral powder with hard magnetic characteristics is pressed together. (2) Smelting: NdFeB magnet melting ingot making equipment, including eq1... Read More

|

|

Magnets are natural magnetite, and the ancient Greeks and Chinese found a natural magnetized stone in nature, calling it "magnetite". This stone magically sucks up small pieces of iron and always points in the same direction after swinging at will. Early navigators used this magnet as their earlies1... Read More

|

|

Regarding the magnetism of magnets, most customers choose cost-effective NdFeB magnets, NdFeB magnets are currently all magnets in the relatively strong magnets, commonly known as "Magneto", many people will ask, since NdFeB is a relatively strong magnet, how many times stronger than some ordinary 1... Read More

|

|

In order to meet the needs of compactness and high efficiency, many (Nd-Fe-B) NdFe-B NdFeB magnets are used in electric power steering structures. It can handle general cuboid and shingle shapes, and can also handle radial radial anisotropic ring magnets. In the case of radial anisotropic ring magn1... Read More

|

|

What are the comparative advantages of powerful magnets and ordinary magnets? Many customers have such a doubt in the choice of magnets, that is, what kind of magnet should I choose, choose a strong magnet or ordinary magnet? The difference between them manifests itself in those areas. Price 1... Read More

|

|

The efficacy of the material without magnets is certainly not the same, what are the advantages and disadvantages between them. The application of magnets is very extensive, due to the variety of material types of magnets, many buyers do not know how to choose. First of all, from the user's1... Read More

|

|

The following are the quotations for two powerful magnets: ①Specification: D6.38*6.35 (nickel-plated) N45 performance grade, the price of the bulk quotation is 0.95 yuan (excluding tax), the material price will fluctuate due to the market situation, please contact us for the latest real-time p1... Read More

|

|

High-quality magnets usually have the following characteristics: beautiful coating (no dents, missing angles, etc.); small tolerances, good size control; strong magnetic force, stable, not easy to demagnetize; good magnetic consistency, no movement; all kinds of certifications are complete of. At p1... Read More

|

|

Neodymium magnets, also known as neodymium iron boron magnets, are tetragonal crystals composed of neodymium, iron, and boron (Nd2Fe14B). In 1982, Sagawa Masato of Sumitomo Special Metals discovered neodymium magnets. The magnetic energy product (BHmax) of this magnet is greater than that of samari1... Read More

|

|

Why are countersunk magnets so popular? What are their advantages? The magic effect of adding countersunk holes to magnets, because the countersunk hole magnets are not used alone, they are used together with other components to combine or fix the screws needed to be used together. What are1... Read More

|

|

What is the structure of the disc magnet? The disc magnet is cut from an ordinary cylinder by a cutting machine according to the specified size, so what is the structure of this circular powerful magnet? Let's discuss together. This disc magnet has two structures of axial magnetization and 1... Read More

|

|

Now there are more and more customers who understand magnet manufacturers through the Internet. Some purchasers are not familiar with the purchase of strong magnets and do not know how to judge the quality. The following content will teach you how to avoid stepping on the pit. With the developm1... Read More

|

|

As the third-generation permanent magnet material, NdFeB magnets have the advantages of small size, light weight and strong magnetic properties, and are widely used in all walks of life. NdFeB magnets are by far the most cost-effective magnets. Unlike other products, there is no clear price tag on 1... Read More

|

|

The factors affecting the machining accuracy of magnets have a great relationship with the processing equipment, tools and processing technology, and the technical level of the operator. In addition, the microstructure of the material also has a great influence on the machining accuracy of the magn1... Read More

|

|

Permanent magnets are permanent magnets, including natural magnets and man-made strong permanent magnets. If you want to know which permanent magnet manufacturer is the best, let me take you to understand the basic knowledge of key strong permanent magnets: Permanent magnet manufacturer Per1... Read More

|